(Created page with " http://wiki.beyondlogic.org/i/LT8490_MPPT_Buck_Boost_Solar_Regulator.png This design is based on a Linear LT8490 High Voltage, High Current Buck-Boost Battery Charge Control...") |

|||

| Line 2: | Line 2: | ||

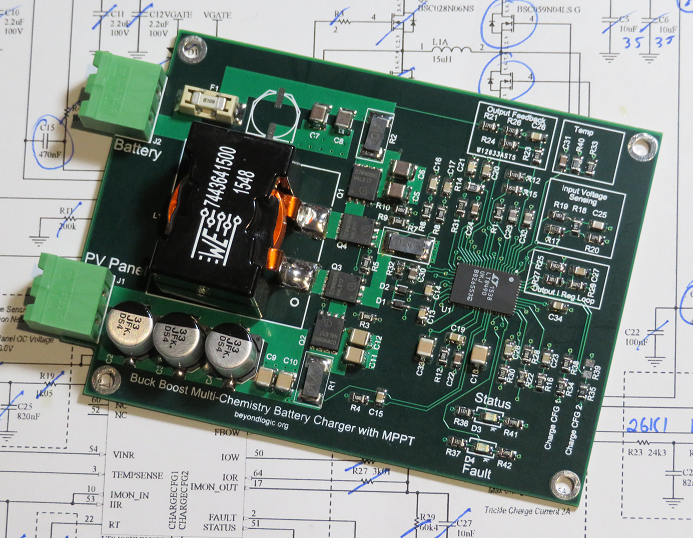

http://wiki.beyondlogic.org/i/LT8490_MPPT_Buck_Boost_Solar_Regulator.png | http://wiki.beyondlogic.org/i/LT8490_MPPT_Buck_Boost_Solar_Regulator.png | ||

| − | This design is based on a Linear LT8490 High Voltage, High Current Buck-Boost Battery Charge Controller with Maximum Power Point Tracking (MPPT). | + | == Design Files == |

| + | |||

| + | Open source design files for the LT8490 based MPPT Buck Boost Solar Regulator can be obtained from [http://circuitmaker.com/Projects/Details/Craig-Peacock-4/LT8490-Buck-Boost-Multi-Chemistry-Battery-Charger-with-MPPT Circuit Maker]. Circuit Maker is a free PCB design tool from Altium. Designs can be imported into Altium Designer. | ||

| + | |||

| + | == Description == | ||

| + | |||

| + | This design is based on a [http://www.linear.com/product/LT8490 Linear LT8490 High Voltage, High Current Buck-Boost Battery Charge Controller with Maximum Power Point Tracking (MPPT)]. | ||

Most PV solar regulators are buck regulators and require the PV panel voltage to be above the battery voltage. This design uses a buck-boost topology and allows the PV solar voltage to be above, below or equal to the battery voltage. | Most PV solar regulators are buck regulators and require the PV panel voltage to be above the battery voltage. This design uses a buck-boost topology and allows the PV solar voltage to be above, below or equal to the battery voltage. | ||

| − | The | + | The LT8490 integrated circuit allows for a PV panel voltage in the range of 6V to 80V. Please note this design uses 63V input capacitors, and these would need to be switched out for panel voltages exceeding approximately 50V. The low voltage shutdown is configured for 5V. |

| − | The LT8490 will charge both Lead Acid and Lithium Batteries between 1.3V and 80V. Again, please observe output capacitor voltage ratings | + | The LT8490 will charge both Lead Acid and Lithium Batteries between 1.3V and 80V. Again, please observe output capacitor voltage ratings. The output caps in this design are rated at 35V but can be replaced with higher voltage ratings, if required. |

The MPPT and charging algorithms are incorporated into the LT8490 and hence no programming is required. | The MPPT and charging algorithms are incorporated into the LT8490 and hence no programming is required. | ||

| − | |||

| − | |||

== Setup == | == Setup == | ||

| − | The design can be heavily customisable to different battery chemistries, voltages and charge currents in addition to various input power sources. This customisation is made predominately through resistor changes, but | + | The design can be heavily customisable to different battery chemistries, voltages and charge currents in addition to various input power sources. This customisation is made predominately through resistor changes, but may also require changes to MOSFETs and Inductors. |

| + | |||

| + | The battery chemistry and the number of charging stages can be set up by resistive divider networks on CHARGECFG1 and CHARGECFG2 pins. Maximum bulk and trickle charging rates can be set with resistor changes in the Output Current Regulation Loop. | ||

Resistor values used are generally selected from the 1% E96 range. | Resistor values used are generally selected from the 1% E96 range. | ||

| Line 26: | Line 32: | ||

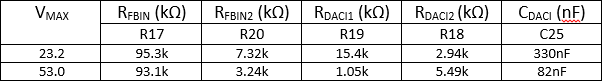

The following table provides some common values for the input voltage sensing and modulation network: | The following table provides some common values for the input voltage sensing and modulation network: | ||

| + | http://wiki.beyondlogic.org/i/LT8490_Input_Voltage_Sensing_Modulation_Network_Resistor_Table.png | ||

| + | Notes: | ||

| − | + | • If powering the circuit from a DC Supply, the VINR voltage divider network should be pulled low. Remove R22. | |

== Input Current Limiting == | == Input Current Limiting == | ||

| Line 38: | Line 46: | ||

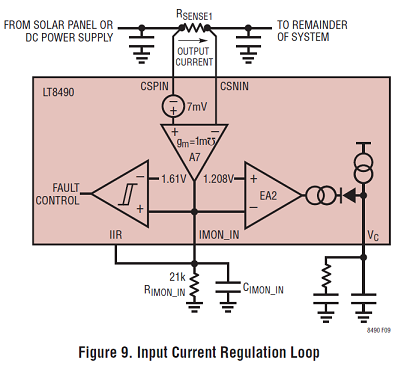

http://wiki.beyondlogic.org/i/LT8490_Input_Current_Regulation_Loop.png | http://wiki.beyondlogic.org/i/LT8490_Input_Current_Regulation_Loop.png | ||

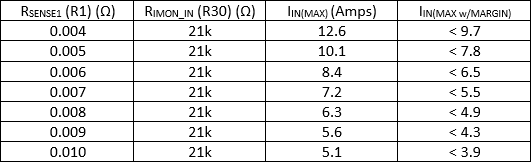

| + | It is recommended to use 21kΩ for RIMON_IN, hence: | ||

| + | RSENSE1 = 0.0505 / IN(MAX) | ||

| + | |||

| + | http://wiki.beyondlogic.org/i/LT8490_Input_Current_Regulation_Resistor_Table.png | ||

CIMON_IN reduces ripple and helps to stabilise the input current limit control loop. A value of 4.7nF to 22nF is deemed adequate for most applications. | CIMON_IN reduces ripple and helps to stabilise the input current limit control loop. A value of 4.7nF to 22nF is deemed adequate for most applications. | ||

| Line 51: | Line 63: | ||

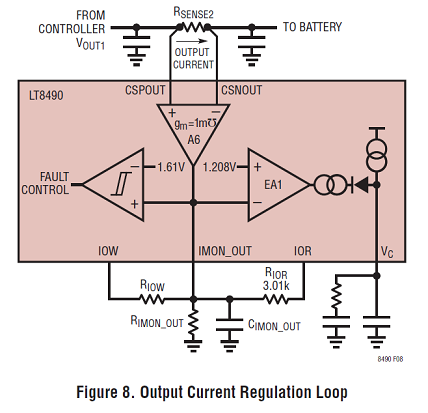

http://wiki.beyondlogic.org/i/LT8490_Output_Current_Regulation_Loop.png | http://wiki.beyondlogic.org/i/LT8490_Output_Current_Regulation_Loop.png | ||

| + | |||

| + | RSENSE2 = 0.0497 / IOUT(MAX) | ||

| + | |||

| + | == Output Feedback Resistor Network == | ||

| + | |||

| + | == Status and Fault Indicators == | ||

Revision as of 10:02, 3 January 2017

Contents

Design Files

Open source design files for the LT8490 based MPPT Buck Boost Solar Regulator can be obtained from Circuit Maker. Circuit Maker is a free PCB design tool from Altium. Designs can be imported into Altium Designer.

Description

This design is based on a Linear LT8490 High Voltage, High Current Buck-Boost Battery Charge Controller with Maximum Power Point Tracking (MPPT).

Most PV solar regulators are buck regulators and require the PV panel voltage to be above the battery voltage. This design uses a buck-boost topology and allows the PV solar voltage to be above, below or equal to the battery voltage.

The LT8490 integrated circuit allows for a PV panel voltage in the range of 6V to 80V. Please note this design uses 63V input capacitors, and these would need to be switched out for panel voltages exceeding approximately 50V. The low voltage shutdown is configured for 5V.

The LT8490 will charge both Lead Acid and Lithium Batteries between 1.3V and 80V. Again, please observe output capacitor voltage ratings. The output caps in this design are rated at 35V but can be replaced with higher voltage ratings, if required.

The MPPT and charging algorithms are incorporated into the LT8490 and hence no programming is required.

Setup

The design can be heavily customisable to different battery chemistries, voltages and charge currents in addition to various input power sources. This customisation is made predominately through resistor changes, but may also require changes to MOSFETs and Inductors.

The battery chemistry and the number of charging stages can be set up by resistive divider networks on CHARGECFG1 and CHARGECFG2 pins. Maximum bulk and trickle charging rates can be set with resistor changes in the Output Current Regulation Loop.

Resistor values used are generally selected from the 1% E96 range.

Input Voltage Sensing and Modulation Network

While the LT8490 utilises a MPPT algorithm, some set-up is required to the input voltage sensing and modulation network to select the maximum panel voltage. Arbitrarily setting VMAX to 80V may not result in the best operation of the LT8490 for all conditions, particularly at low input voltages.

The following table provides some common values for the input voltage sensing and modulation network:

Notes:

• If powering the circuit from a DC Supply, the VINR voltage divider network should be pulled low. Remove R22.

Input Current Limiting

The maximum input current limit should be set at approximately 120 to 130 percent of the maximum current capability of the PV panel. The LT8490 will digitise the current reading and use it in its MPPT algorithm. Setting this value higher than necessary may reduce the accuracy of the MPPT calculations.

The maximum input current limit is set by the input sense shunt RSENSE1 (R1) and converted to a voltage using RIMON_IN (R30) before being digitised (IIR/Input Current Read pin).

It is recommended to use 21kΩ for RIMON_IN, hence:

RSENSE1 = 0.0505 / IN(MAX)

CIMON_IN reduces ripple and helps to stabilise the input current limit control loop. A value of 4.7nF to 22nF is deemed adequate for most applications.

Minimum Operating Voltage

The minimum operating voltage to enable the switching regulator is set via the R12/R15 voltage divider. The default setting in this design is 5V, the minimum operating voltage of the LT8490.

Charge Current Limiting

The maximum charging current is set by the output sense shunt resistor RSENSE2 (R2) and converted to a voltage using RIMON_OUT (R29).

RSENSE2 = 0.0497 / IOUT(MAX)